VENTUS Compact floor-mounted air handling units are energy-saving units equipped with a rotary heat wheel or hex counter-flow heat exchanger, EC motors in the fan wall system, Mini-Pleat filters and integrated controls (Plug&Play).

The compact units in the floor-mounted version are intended for installation in technical rooms as well as outside the building.

The units are made of mineral wool insulation panels covered with Aluzinc sheet (AZ 150). The panels are attached to a steel supporting structure that ensures the rigidity of the entire unit.

The units are equipped with:

The units are configured and ready for operation immediately after connecting (Plug&Play).

The compact units in the floor-mounted version are equipped with a rotary heat wheel or hex counter-flow heat exchanger, ensuring heat recovery efficiency up to 90%.

The multi-fan assembly of the fan wall type ensures minimal energy consumption and optimal device operating parameters.

The compact air handling units in the floor-mounted version are equipped with multifunctional controls integrated with the unit (Plug&Play).

Controls enables remote control of the unit operation through the factory VTS visualisation or the remote HMI Advance desktop.

The integrated controls in combination with the factory wiring means that VENTUS Compact units are offered in the Plug&Play standard.

The proper functioning of the air handling unit depends on the effectiveness of the applied filtration.

Specialists recommend changing filters 2 to 4 times a year. Original, high-quality filters for VENTUS AHUs are available in the VTS online store.

You can easily choose filters for your AHU. Use the search engine, entering the VTS AHU number to order the correct set of filters.

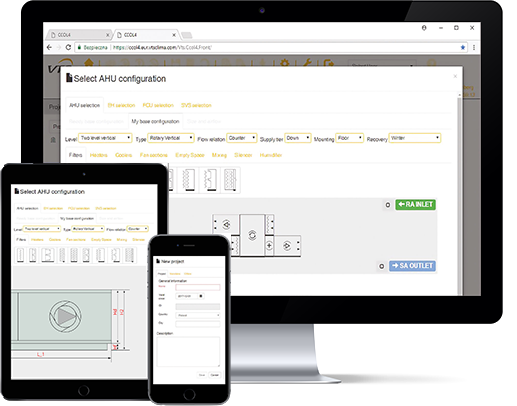

ClimaCAD OnLine 4 (CCOL4) is a proprietary VTS device selection software. The software uses the latest technologies and programming platforms. The system is available from anywhere in the world, any device with a web browser and access to the Internet is sufficient.

The software includes both modules for optimal device selection in terms of parameters and costs as well as innovative generators of Revit objects or 2D and 3D dwg files. The generators ensure immediate availability of .rfa and .dwg files for any device configuration. The system offers the ability to automatically generate descriptive and parametric technical specifications of selected devices. Full device parameters are available in .pdf, .html as well as .rfa files.

Check and download the files related to the product.

Check the facilities that use our solutions.

VENTUS Compact floor mounted are energy-saving units equipped with:

Capacity: from 840 m3/h to 16,500 m3/h

Energy recovery: recovery efficiency up to 90%

Placement: on the floor

The VTS Group offer includes compact air handling units installed in various places. Devices are designed for mounting under the ceiling and on the floor. Both types have similar energy recovery efficiency. Each variant provides up to 90% recovery efficiency. You can also buy from us compact air handling units with vertical duct connection.

Compare solutions and check which one will work best in your facility.

Thanks to the investment in modern ventilation systems that you will find in our assortment,

you can reduce the cost of operating the facility. Compact air handling units are equipped with heat exchangers enabling recuperation. It means that they take the heat from the air blown out of the building and transfer it to the air that reaches the interior. The temperature exchange allows to reduce energy losses.

Contact us and find out what characterizes compact floor mounted air handling units and check how they work and what you can benefit from them.

The compact floor mounted units can be installed indoors and outdoors.

They are made of panels insulated with mineral wool and covered with Aluzinc (AZ 150) sheet. The panels are installed to the steel supporting structure ensuring the rigidity of the whole unit. The devices are factory configured and ready to work immediately after connecting (Plug & Play).

Therefore, their installation is extremely simple and does not take much time.

High energy efficiency is one of the most important advantages of our units. It allows for the recovery of thermal energy, which translates into lower bills for heating and electricity of buildings.

The compact floor mounted units are equipped with a rotating or hexagonal heat exchanger. What ensure heat recovery efficiency up to 90%.

Compact air handling units in the floor mounted version are equipped with multifunctional controls integrated with the unit (Plug & Play). It does not require complicated configuration - the device is ready to work right after installation.

The controls enables remote management of the AHU operation through factory made VTS visualization or remote HMI Advance desktop.

Efficient operation of the air handling unit depends on the effectiveness of the filtration used, therefore it is recommended to replace the filters 2 to 4 times a year.

Original filters for VENTUS AHUs are available in the VTS Groupe online store.

They can be easily selected using the product search engine on the website.

It is enough to enter the serial number of the control panel.

ClimaCAD OnLine 4 (CCOL4) is proprietary software for the selection of VTS air handling units. It uses the latest technologies and programming platforms. The system is available remotely from any place and device - all you need is access to the Internet.

The software contains modules for optimal selection of devices in terms of parameters and costs. It also gives you access to innovative Revit object generators and 2D and 3D DWG files. The generators provide instant availability of .rfa and .dwg files for any device configuration.