The compact air handling units with heat pump are intended for installation in technical rooms as well as outside the building.

The units are made of mineral wool insulation panels covered with Aluzinc sheet (AZ 150). The panels are attached to a steel supporting structure that ensures the rigidity of the entire unit.

The units are equipped with:

The units are configured and ready for operation immediately after connecting (Plug&Play).

Design

The location of the heat pump condenser and evaporator on either side of the rotary heat exchanger ensures that these components complement each other in terms of heat recovery, resulting in maximum efficiency for the entire system.

Components

Excellent heat and moisture recovery is provided by a high efficiency sorption rotary heat exchanger. The heat recovery effect is enhanced by a heat pump based on six-row heat exchangers with a developed heat transfer surface.

Smooth heat recovery capacity adjustment

The system achieves smooth heat capacity adjustment through an electronically controlled stepper motor of rotary exchanger and the applied inverter compressor with a DC motor. The heat pump system features an additional controller equipped with sensors, which fully controls the heat pump system parameters.

The compact air handling units with heat pump are equipped with multifunctional controls integrated with the unit (Plug&Play).

Controls enables remote control of the unit operation through the factory VTS visualisation or the remote HMI Advance desktop.

The heat pump control system is integrated and consistent with the control system of the entire air handling unit. All heat pump parameters are available in the AHU control interface, but for service purposes it is also possible to directly connect the operator panel to the heat pump controller.

The integrated controls in combination with the factory wiring means that VENTUS Compact units are offered in the Plug&Play standard.

The proper functioning of the air handling unit depends on the effectiveness of the applied filtration.

Specialists recommend changing filters 2 to 4 times a year. Original, high-quality filters for VENTUS AHUs are available in the VTS online store.

You can easily choose filters for your AHU. Use the search engine, entering the VTS AHU number to order the correct set of filters.

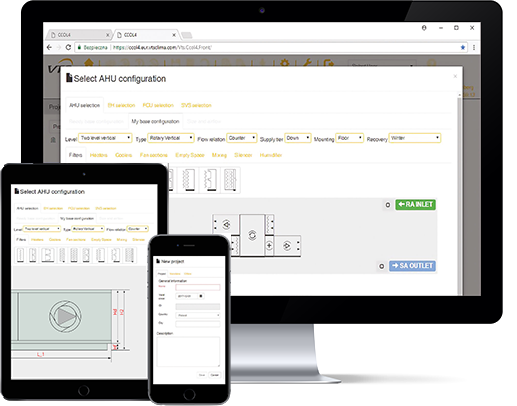

ClimaCAD OnLine 4 (CCOL4) is a proprietary VTS device selection software. The software uses the latest technologies and programming platforms. The system is available from anywhere in the world, any device with a web browser and access to the Internet is sufficient.

The software includes both modules for optimal device selection in terms of parameters and costs as well as innovative generators of Revit objects or 2D and 3D dwg files. The generators ensure immediate availability of .rfa and .dwg files for any device configuration. The system offers the ability to automatically generate descriptive and parametric technical specifications of selected devices. Full device parameters are available in .pdf, .html as well as .rfa files.

Check and download the files related to the product.

Check the facilities that use our solutions.