Warehouse/workshop heating methods

A warehouse is not only a facility where goods are stored, but also a place of work. As is a workshop where every day people work on repairs, assembly, and processing. Heating such premises is not only a matter of comfort, but a requirement under OHS regulations. What are the best ways of heating a warehouse or workshop in winter?

Workshop heating and anti-carbon policy

Heating premises in a temperate climate is necessary due to low temperatures prevalent for more than half a year. For thousands of years, people have used various methods to improve the thermal comfort of homes and workplaces. Not so long ago, only a few decades, this was not a major problem. All you needed was an appropriate furnace, coal or oil, and the workshop or hall were comfortably warm.

Recently, new legislation came into force, its scope including emission levels. The green policy has made many heating solutions and techniques no longer usable. Therefore, new green solutions are sought, which will also be cheap to assemble and use, and will result in energy savings. Help comes from new technologies such as air conditioning with recuperators, ventilation with heating and heat pump, or air curtains and water heaters.

Warehouse heating – technical problems

Warehouse or workshop heating must also meet certain technical requirements. These areas are characterised by a large volume and a lack of partitions. Moreover, in most cases, these facilities are used temporarily, during the day, sometimes even for 8–10 hours. For this reason, the heating system is expected to:

- raise temperature quickly and effectively (in the morning) in the areas where people are present,

- have a capacity to heat large and empty spaces,

- be easy start-up and immediate readiness to work.

Conventional heaters certainly do not posses any of these features. They distribute hot air via convection. For warehouses that are several meters high, heating the interior requires time. This phenomenon may be limited by destratificators, however even with their help, employees sometimes have to wait for their workplace to warm up through half their shift.

How to warm up a warehouse or workshop in winter quickly – minimizing heat losses?

The first step for planning heating of a workshop or warehouse is always to look for ways of reducing heat losses. Increasing the temperature to a certain level will take longer and incur higher costs if the facility is not airtight and full of thermal bridges. It is therefore worth it to insulate it with Styrofoam, mineral wool, or PUR foam. One needs to insulate not only the walls, but first and foremost, the roof, which is through where most heat escapes.

Eliminating or limiting these losses also requires paying attention to windows and doorways. It is paramount to make sure they have proper seals and even equip them with additional protective film. In the case of entrances or gateways, the air curtain is a good solution, which will prevent hot air from escaping outside. The use of the so-called air curtain with a heating function will provide additional heat in the doorway zone.

Best ways of heating a warehouse

Under the above conditions, solutions are required to ensure targeted thermal radiation emissions. Its carrier may be both infrared emissions and heated air. The first is a new solution that is only starting to gain popularity with potential users. Solutions such as infrared radiators or infrared panels still are still surrounded by some distrust.

Hot air heating systems, which also include a number of solutions, are much more popular. These are the best ways to warm up a warehouse or workshop also because they are cheap in operation and environmentally friendly. This group includes:

- air conditioning with a heating function,

- water, gas, and oil heaters,

- forced air furnaces.

Air curtains are also a forced air system. Their role in the heating system is quite significant. Although they themselves do not provide much heat, they prevent it from being lost.

Heating a warehouse with air conditioning

Air conditioning with heating function is one of the latest proposals in the field of heating facilities. It has long been known that air conditioning is not seeing much use in winter. Outdoor temperatures are low and indoor spaces do not need cooling. The use of this system would be justified if the indoor temperatures were high. However, in winter, central heating systems are used since it can regulate the temperature in the building.

Unused air conditioning does not need to be inactive. If it has appropriate functions, it can be used to generate heat as well. In the summer, heat is removed from the building and replaced by cool air via the ventilation system. In winter, this heat may be used to warm up rooms.

A very interesting solution produced by VTS Group is a ventilation unit equipped with a rotary regeneration unit and a heat pump. The combination of these two elements into a single compact unit has resulted in an extremely efficient solution for recovering energy from removed air at more than 90%. In addition to the energy recovery function, the internal heat pump is also used for heating rooms, e.g. storage or workshops. An important function a device configured like that is also the possibility of cooling air in summer and supplying fresh air to the facility throughout the year.

How to effectively raise the temperature in a warehouse using hot air?

One of the newer ways of heating workshop or storage areas is to use air as a heating medium. The heating system can have two forms, i.e.:

- forced air heating from a furnace,

- water heater or gas heater.

Each of these systems operates on the principle of passing a cold air stream close to hot water pipes or furnace. The air absorbs the heat and then is blown inside the warehouse or workshop.

Another difference is where the system takes air from. In the case of water heaters, the fan drives it directly from the room. In the case of forced air furnaces, it is taken from the rooms via intakes and directed to the furnace powered by natural gas, LNG, or electrically. This installation is comprised of a forced air furnace and a system of ducts and grates. The system may also be equipped with air filtering, drying and cooling functions.

How does a water or gas heater system for warehouses/workshops work?

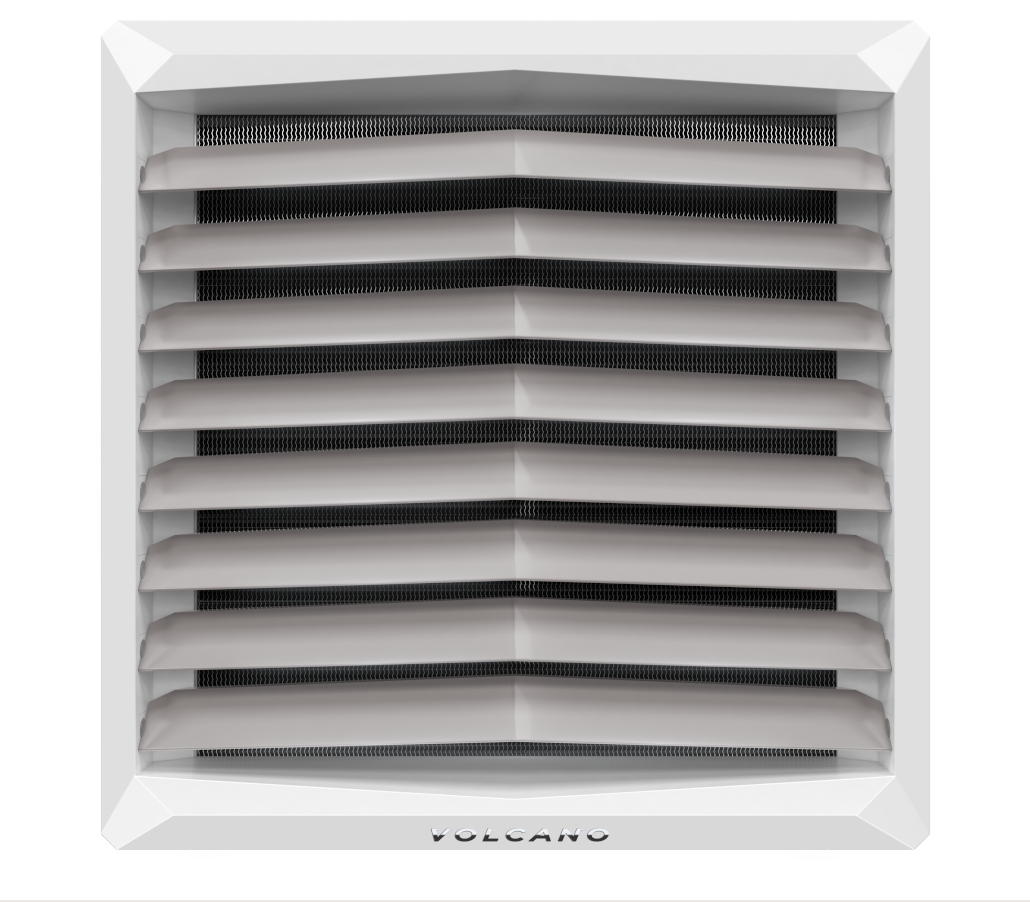

When considering how to effectively increase the temperature in a warehouse, it is also worth to look into water and gas heaters. Their grates are equipped with a slat system. The slat setting allows the user to redirect the air to the zone to be heated. Grate placement at an appropriate height directs the air straight to the zone were people are present. In addition, the slate setting can be adjusted.

To operate such a heating system efficiently requires a hot water system to be placed near the warehouse. The air sucked in by the fan passes through the hot pipe system and, after heating, returns to the room. The same is true for gas heaters, but in their case heat is generated by burning gas.

English

English Polski

Polski Germany

Germany LATAM

LATAM Bulgaria

Bulgaria Estonia

Estonia France

France Hungary

Hungary India

India Italy

Italy Kazakhstan

Kazakhstan Romania

Romania Czech Republic

Czech Republic Ukraine

Ukraine United Arab Emirates

United Arab Emirates Latvia

Latvia Lithuania

Lithuania United States of America

United States of America

Turkey

Turkey