COMPACT AIR HANDLING UNITS WITH HEAT PUMP

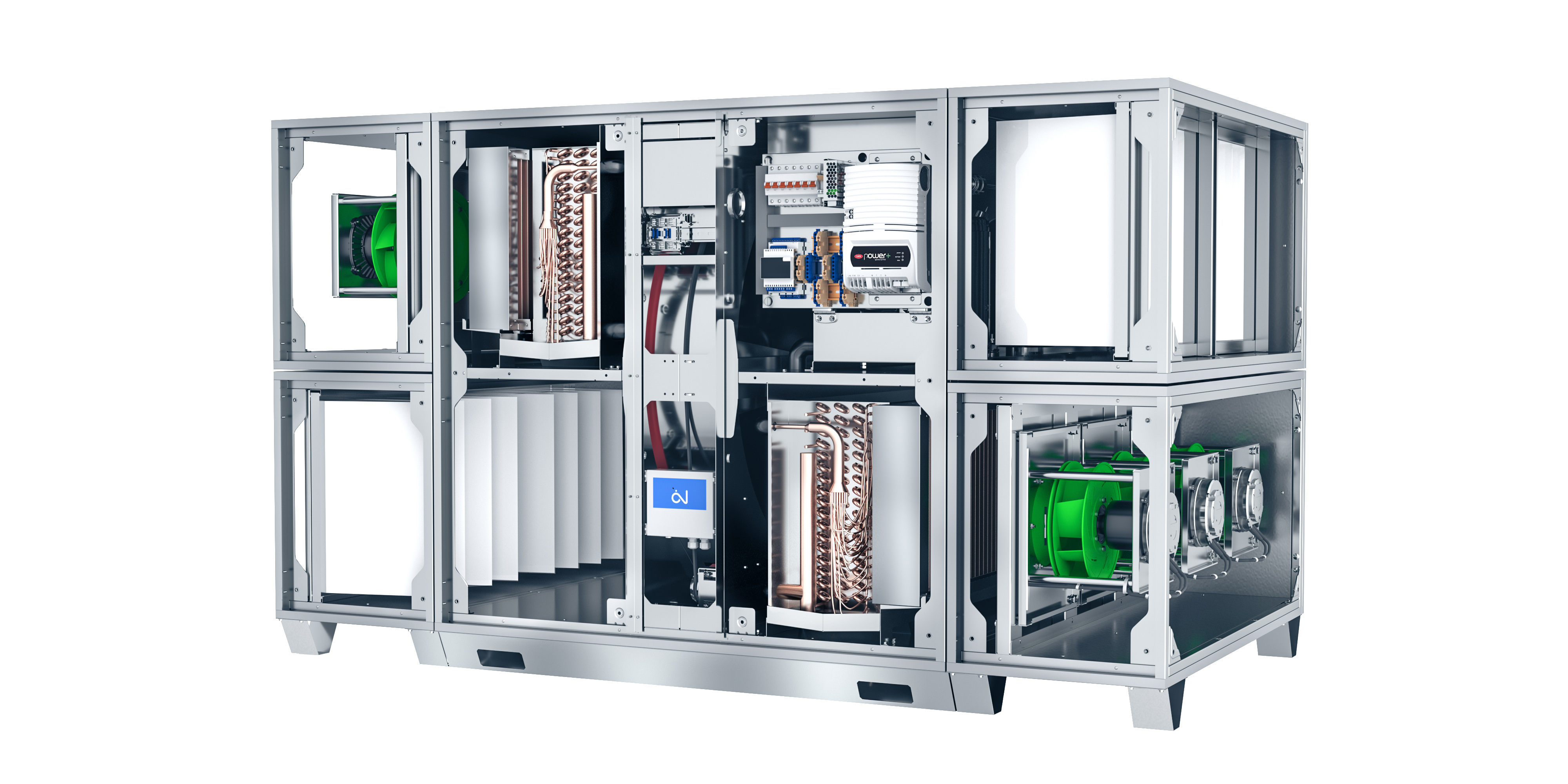

The heat pump in VTS

Group units is a pressurised built-in freon system. The reversible cooling

system with direct evaporation contains: an evaporator, a condensor, a

compressor, a 4-way valve, and cooling fixtures including electronic compressor

valves, which dynamically match the flow of the agent to the current unit’s

parameters.

The heat pump is designed for cooling or heating supply air to rooms

depending on the time of year and requirements of the building. The newest

available unit with an integrated heat pump from VTS Group is the VVS075c model

with a nominal capacity of 7500 m3/h. Currently the typical range of

units with built-in heat pumps consists of five machines covering from 1200m3/h

to 7500 m3/h.

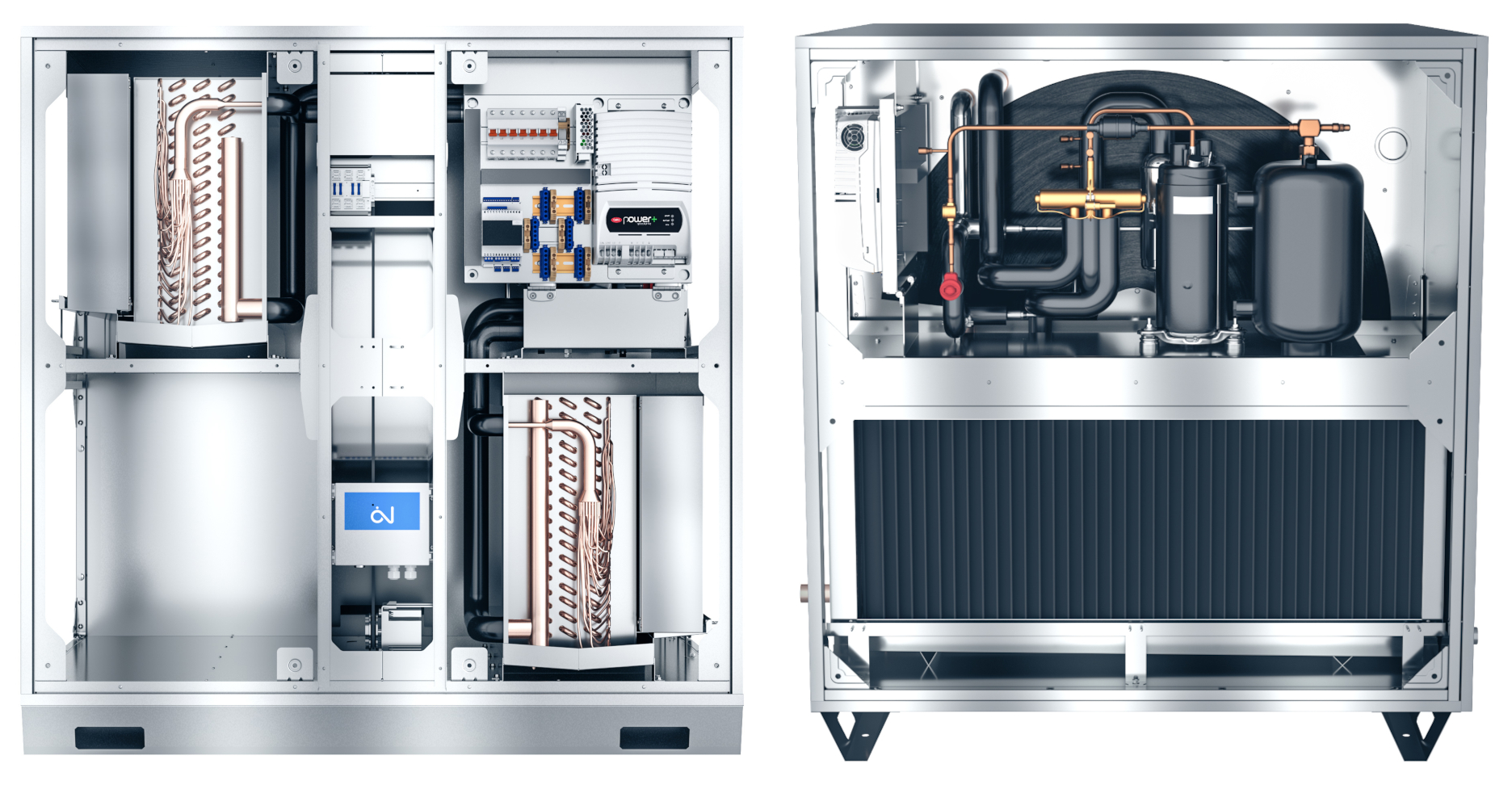

PERFECT CONFIGURATION: ROTARY HEAT WHEEL + HEAT PUMP

The R & D department in VTS Group has created the most effective configuration of the ventilation units equipped with high-performance sorptive rotary heat wheel regenerator with heat pump. The positioning of the heat pump exchangers on both sides of the rotary heat exchanger (the main energy recovery element) has an array of advantages including structural and operational.

Air is supplied to the heat pump evaporator after

the passage by the rotary heat recovery exchanger which causes a considerable

reduction of demanded power of the heat pump, especially in cooling mode. On

the other hand, when in heating mode, the condensor is not exposed to low work

temperatures because first the air passes through a rotary generator. In

practice, this indicates that the system is working efficiently even in

extremely low outside temperatures without the necessity of an additional heat

source.

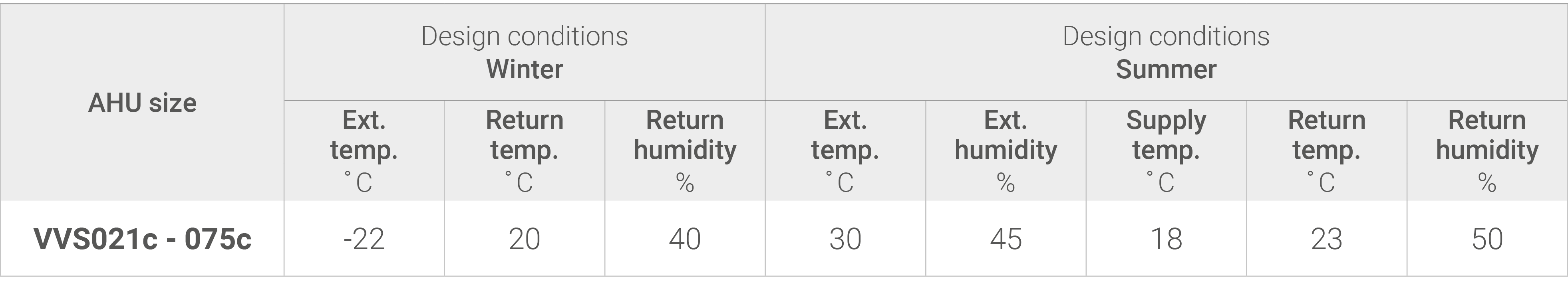

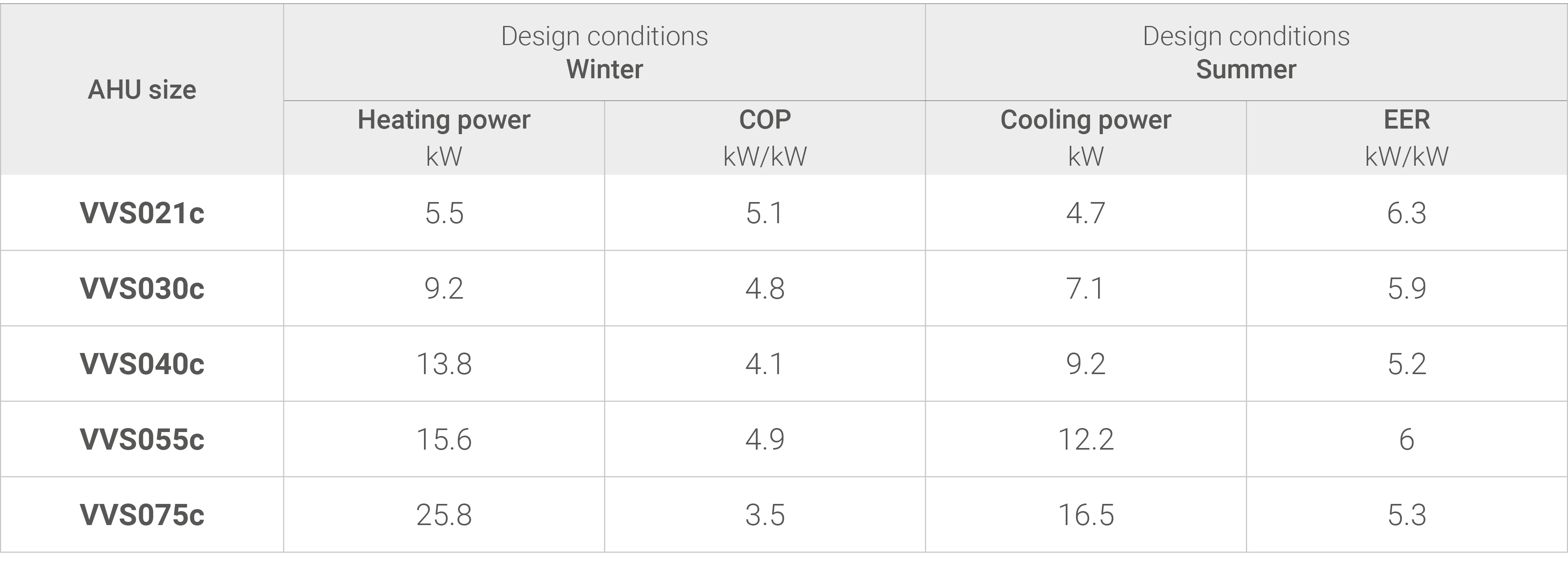

COMPACT AHU WITH HEAT PUMP WORK PARAMETERS

VTS Group heat pumps have been designed for a wide

range of planned conditions without the need for applying the pre-heater for

low external temperatures. In the summer, the machines cool the air to a

comfortable temperature when the outside temperatures are high.

Cooler/heater power, COP/EER on planned conditions

with airflow Exhaust/Supply=0.9 (remaining calculated conditions in accordance

with the table below)

SPACE SAVING

Optimal sizes of the VTS Group units with heat

pump allow

for the installation of the machines in spaces of limited area e.g. in existing

machine rooms. In traditional cooling systems space is needed to install a

condensor and copper pipe installation, but in the case of ventilation systems

with built-in heat pumps, the whole system is integrated into one device which

considerably reduces the need for space. Additionally, the lack of necessity to

install a condensor onto the front of the building is a huge advantage,

especially on protected buildings and in conservation areas.

SMOOTH POWER REGULATION OF THE HEAT PUMP COOLER

VENTUS Compact units with a rotary heat exchanger and built-in heat pump are equipped with an inverter compressor with a DC motor for smooth regulation of the heater and cooler power. An advantage of the solution is the easy setting of the unit’s operation according to the building’s requirements. The compressor rotary speed changes which allows accurate control of the coolant system and perfect regulation to the current demand. Such a method of regulation reduces energy consumption and the temperature of the room is smoothly regulated.

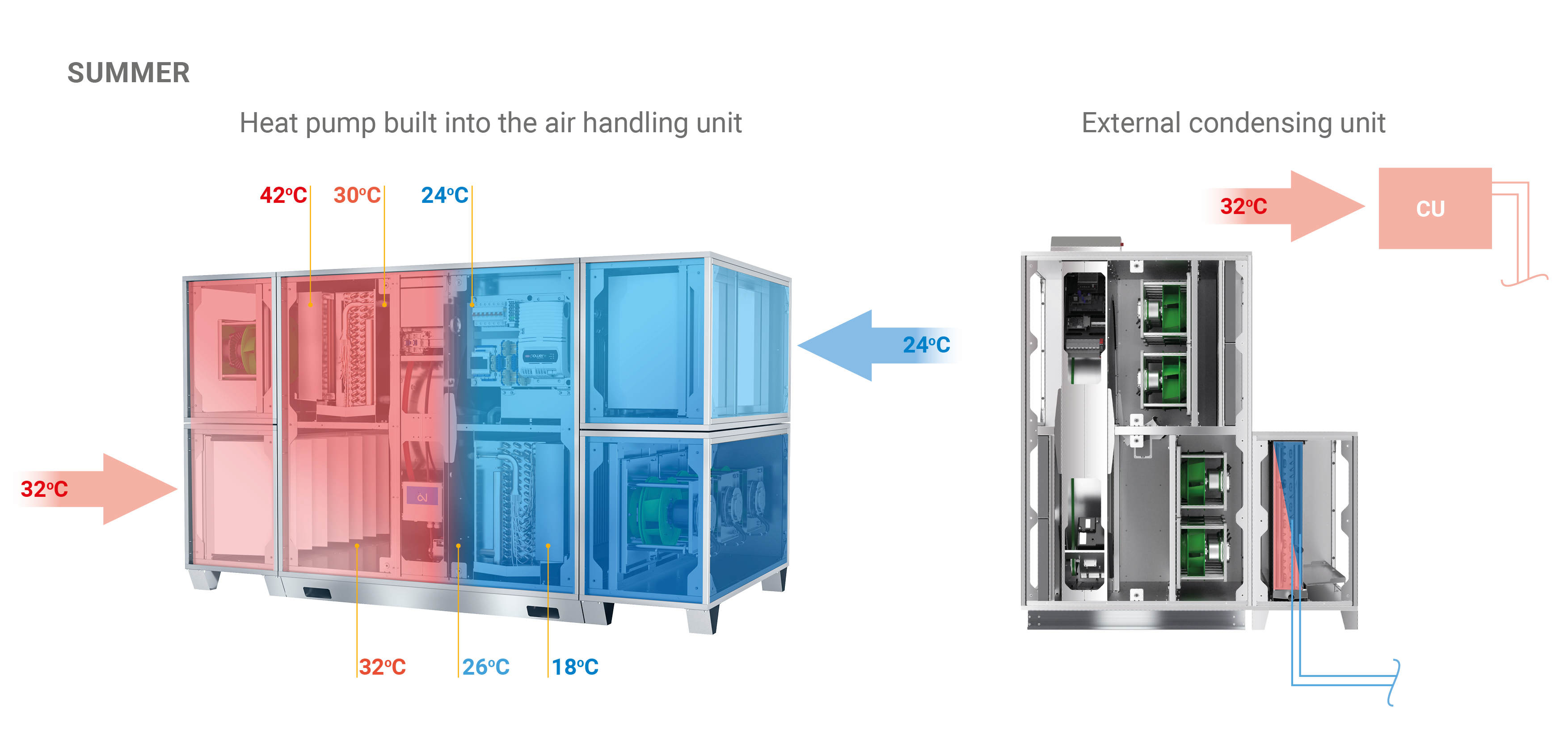

SUMMER-COOLING MODE

Outside air first flows through the rotary heat

exchanger. Because the internal air temperature of the room is lower than

outside, the rotary exchanger some of the cool air, causing a reduction in the

outside air temperature. Thanks to this, the temperature of the condensation is

lower and as a result reduces electricity consumption in the compressor compared

to typical solutions where an external co-operating unit with an air cooling

duct is used. Additionaly, use of the compressor with adjustable rotary

speed additionally limits the energy

consumption.

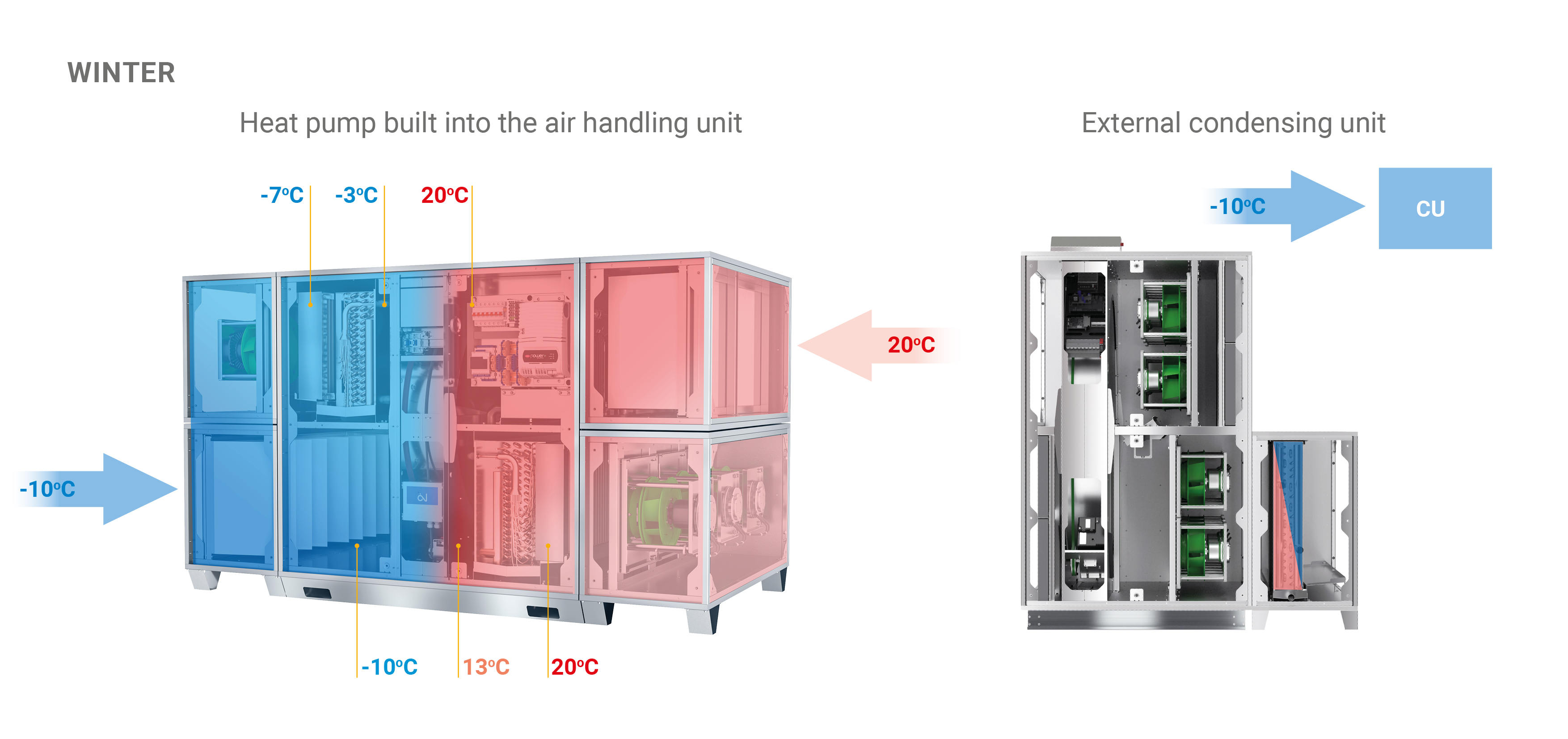

WINTER-HEATING MODE

Changing the machine’s work mode from cooling to

heating takes place after activation of the 4 way-valve into heating mode. The

evaporator and condensor change functions. Outside air, after passing through

the heat exchanger, in this case operating in standard mode, is heated by the

warmer exhaust air from the room. Thanks to the function of the

high-performance rotary heat exchanger, a significant amount of energy is

recovered. In the second stage, energy is recovered by the heat pump, which

also regulates the temperature of the air supplied to the room.

ADVANTAGES OF VTS GROUP AIR HANDLING UNITS WITH HEAT PUMP

The main advantages and benefits of VTS Group units with integrated heat pumps are:

- A wide range of functions for external air

temperatures in summer and winter.

- Possibility of reducing the efficiency of the

exhaust air relative to the supply air, even up to 20%

- Units equipped with factory-installed VTS Group control

systems – Plug & Play fully prepared for operation immediately after

connection to the power supply. Easy start-up of the machine without the need

for a service engineer.

- Manufacturer’s guarantee on final units and heat

pump products

- The installed heat pumps do not require service of

the coolers while running the ventiliation unit.

- Ventilation, heat recovery, heating and cooling –

everything in one cluster from one manufacturer.

- Cooling of the supply air in the summer and

reducing costs of heating supply air for the rest of the year.

English

English Polski

Polski Germany

Germany LATAM

LATAM Bulgaria

Bulgaria Estonia

Estonia France

France Hungary

Hungary India

India Italy

Italy Kazakhstan

Kazakhstan Romania

Romania Czech Republic

Czech Republic Ukraine

Ukraine United Arab Emirates

United Arab Emirates Latvia

Latvia Lithuania

Lithuania United States of America

United States of America

Turkey

Turkey