The units are selected using the ClimaCAD OnLine software.

The VENTUS VVS modular air handling units are made of polyurethane panels covered with Aluzinc coated sheet metal (AZ 150) mounted on an internal skeleton made of metal profiles.

The VENTUS VVS units have an extensive sealing system, among others, sealing fins ensuring labyrinth sealing, a thermal insert that allows to break the thermal bridge, as well as a roofing system.

The VENTUS VVS modular air handling units meet the highest energy-efficiency requirements.

The devices can be equipped with various heat recovery options:

The maximum recovery efficiency reaches 92%.

Units with a capacity of up to 3000 m3/h are equipped with energy-saving EC motors as standard.

All units are available with multi-functional controls that performs advanced energy-saving functions based on measurements of air quality parameters.

Controls in the VENTUS VVS air handling units regulates all utility parameters and functions of energy optimisation based on the measurement of air quality parameters.

Visualisation or a remote HMI Advance desktop, which enables remote control of the unit, are available as standard.

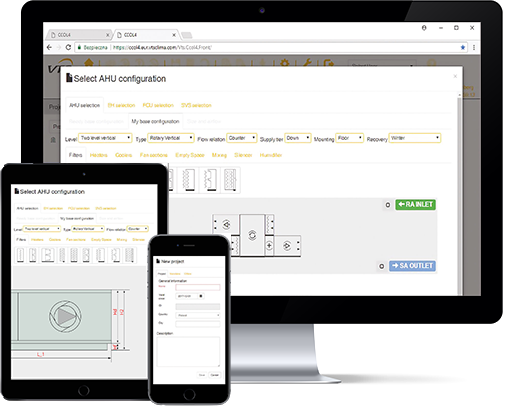

ClimaCAD OnLine 4 (CCOL4) is a proprietary VTS device selection software. The software uses the latest technologies and programming platforms. The system is available from anywhere in the world, any device with a web browser and access to the Internet is sufficient.

The software includes both modules for optimal device selection in terms of parameters and costs as well as innovative generators of Revit objects or 2D and 3D dwg files. The generators ensure immediate availability of .rfa and .dwg files for any device configuration. The system offers the ability to automatically generate descriptive and parametric technical specifications of selected devices. Full device parameters are available in .pdf, .html as well as .rfa files.

Check and download the files related to the product.

Check the facilities that use our solutions.