VENTUS Compact - new AHU line by VTS

VTS has the pleasure of introducing our new line of compact air handling units under the name of VENTUS Compact.

The main distinguishing features of the new line product line are:

- solid structure with compact dimensions,

- high efficiency energy recovery system

- energy saving and silent EC motors of IE4+ class,

- long lifetime Mini-Pleat air filters,

- advanced control systems, and power circuits, which are pre-installed and configured by the manufacturer

The units are available in two styles, either ceiling suspended or floor mounted.

|

|

Energy recovery

All VENTUS Compact air-handling units comply with the provisions of the directive KE 1253 regulation, commonly known as ECODESIGN. The compliance with the regulation has been fulfilled by applying energy recovery systems reaching up to 92% (suspended units) and up to 86% (for floor mounted ones).

|

|

|

|

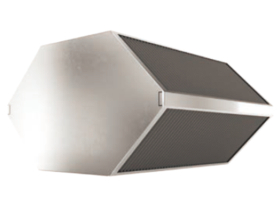

Hexagonal counter flow energy recovery blocks for suspended units |

Rotary wheels for floor-mounted units |

The suspended units have been equipped with high-efficiency counter-flow hexagonal recuperators with an additional by-pass for frost protection. The recuperator provides summer and winter energy recovery that transfers from the exhaust airstream to the supply airstream ensuring excellent separation between streams (no cross-contamination).

In the floor-mounted air-handing units, high-efficiency rotary wheels have been used with an EC motor based drive. This rotary wheel ensures that energy recovery is provided with latent heat recovery during all seasons.

The natural humidifying transfer of the rotary wheel significantly improves the quality of supply air in the winter, thus preventing excessive air dryness in the heating process. In systems with air humidification, the application of energy recovery systems based on rotary wheels significantly reduces humidification cost. The automation system prevents the freezing of the rotary wheel in the winter and optimizes the efficiency of energy recovery by measuring the air flowing through the exchanger and smoothly adjusting the rotating speed of the rotor, as well as by additional means of air flow management. The drive of the rotating exchanger is based on EC motors, the efficiency of which is essentially constant, regardless of its revolutions settings.

In the majority of applications, no condensate is dropped from the rotary wheel section which is an additional benefit, especially for outdoor installed units

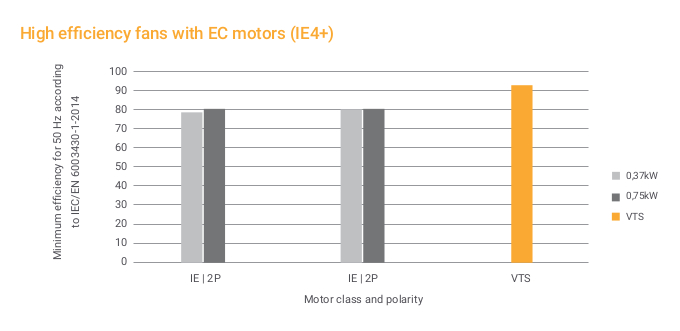

EC motors

The fan sets have been equipped with high-efficiency EC motors with an energy-saving class that greatly exceeds the requirements of motor efficiency with IE4 class.

The most important advantages of EC motors include:

- easy control,

- highly efficient electric power transformation into mechanical power,

- essentially constant high efficiency performance, across a wide range of revolutions,

- small frame sizes,

- silent operation,

|

|

Mini-Pleat filters

Mini-Pleat technology represents a new approach to air filter design and manufacturing. This change in design ensures a much larger filtration surface which allows for an equivalent absorbency with the same surface space as occupied by traditional panel filters. The filters are composed of ultra-thin microfibers, which are covered by a special, condensed binder. Adhesion balls ensure even air flow and filter strength. Mini-Pleat filters have been tested and designed for applications in ventilation systems that require medium to high efficiency filtration, like: hospitals, healthcare centers, educational institutions, microprocessors production plants and many others. A Mini-Pleat filter is characterized by a much greater durability than the traditional ones.

As a standard, the devices are equipped with the following Mini-Pleat filters

- on the supply side - in EU 7 class

- on the exhaust side - in EU 5 class

Optionally an additional air filter is available in EU9 class

|

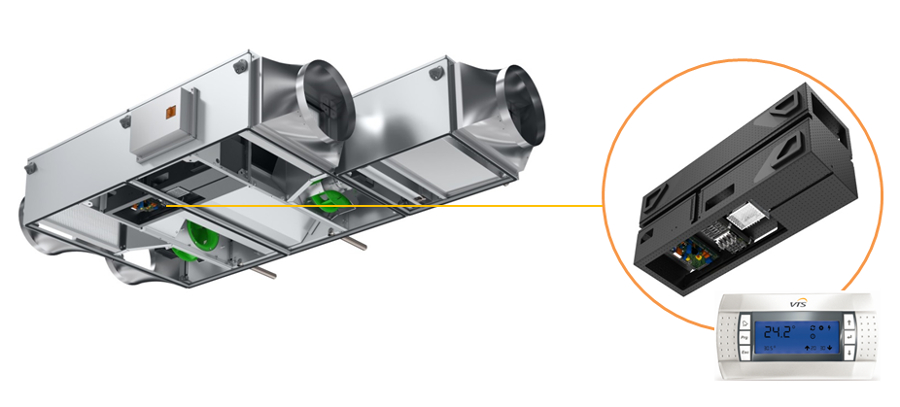

Integrated multi-functional automation

Compact air-handling units are delivered as fully factory cabled with pre-installed and pre-configured control systems according to application pointed by CCOL4 selection tool.

The only elements requiring addition installation are control system parts related with additional air treatment functions, also duct temperature sensors and actuators. The dampers, are not factory mounted to the units, which give the customer the possibility to choose the best mounting location. Also, in the case of additional air treatment functions added to the main unit, the damper can be installed downstream of the last component.

All power supply components are wired through the factory mounted junction-box mounted on the external AHU wall.

Upon the placement of the controls inside the housing we gain additional space, which in traditional solutions must be earmarked for supply and control switching stations.

Apart from the basic algorithms of control and protection of air-handling unit operation, the installed controls also ensure:

- continuous monitoring of filter contamination,

- electronic measurement and automatic adjustment of performance, i.e. the function which adapts fan power to system requirements,

- the maintenance of fan operating levels, regardless of the level of filter contamination and the level of opening of the by-pass damper,

- a dynamic algorithm of forecasting the freezing condition, and thus the extension of recovery operation within the range of low temperatures,

- adaptation of fan operational point to actual ventilation system needs,

- communication with BMS systems

- visualization of air-handling unit operation by means of an Internet browser

|

Examples of visualisations of automation functions in VENTUS air-handling units.

|

|

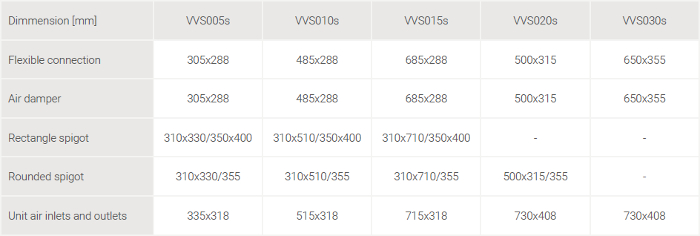

Compact suspended air-handling units

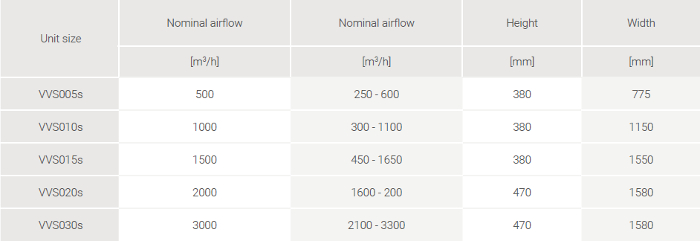

The scope of type series of suspended air-handling units covers 5 units with the capacity between 250 m3/h and 3,300 m3/h.

Type series of suspended air-handling units

|

Normal airflow - upon the application of additional functions, the increase of minimum air speeds may be required.

|

|

A compact block consists of:

- High efficiency counter-flow hexagonal energy recovery with a by-pass function that protects the exchanger against freezing.

- Energy-saving and silent fan sets with EC motors with energy-saving class IE4+,

- Highly absorbent Mini-Pleat air filters with respective filtration classes EU7 on the supply side and EU5 on the exhaust side

- Build-in advanced controls enabling unit’s monitoring, protection and performance optimization.

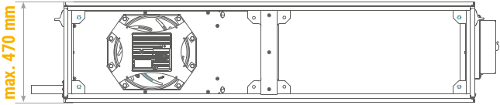

Low height of devices should also be taken into account, since it enables flexible device mounting.

|

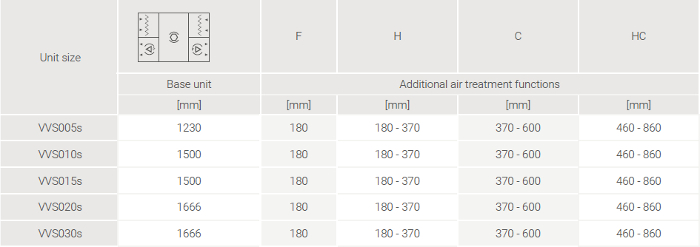

The suspended units are offered on the basis of functional blocks and additional supplementary functions, i.e. the functional add-ons, such as: an EU9 air filter, a water and electric heater, a water cooler with direct expansion as well as silencer, and empty section.

The length of the compact air-handling unit with recovery and additional optional functions

|

Duct outfits

|

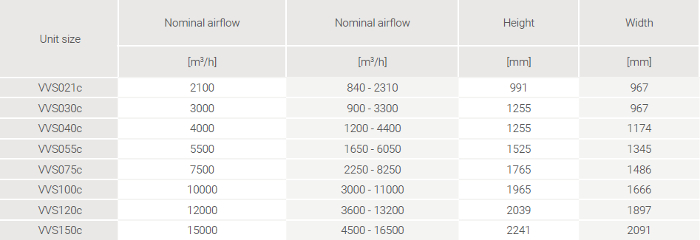

Compact standing air-handling units

The scope of type series of standing air-handling units covers 8 standing units with the capacity between 840 m3/h and 16,500 m3/h.

Type series of standing air-handling units.

|

Normal airflow - upon the application of additional functions, the increase of minimum air speeds may be required

Height- with 90mm frame

|

|

|

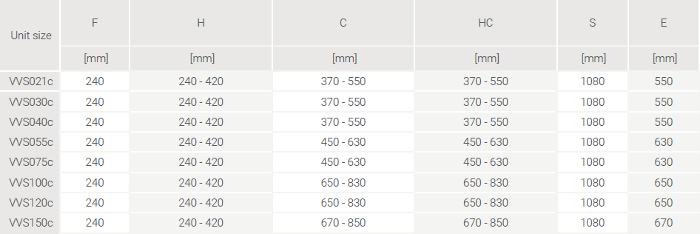

A compact block consists among others of:

- A highly-efficient rotary wheel with a drive based on an EC motor of IE4+ class,

- Energy-saving and silent fan sets with EC motor of IE4+ class

- Highly absorbent Mini-Pleat air filters with respective filtration classes EU7 on the supply side and EU5 on the exhaust side,

- The in-built system of advanced control and protection automation with the optimization function of device operation.

Lengths of base units

|

Lengths of additional air treatment functions

|

Undoubtedly a unique feature of compact air-handling units is the fact With no doubt, the strongest advantage of suspended units is the fact that at the last stage of their manufacturing all operating parameters of the unit are factory set, making them ready to run just after installation. Both motor operating parameters and their automation are pre-configured and the whole system is tested before the shipment to the customer.

Sizes VVS010s and VVS015s are available for sale, and the remaining sizes of suspended and standing air-handling units shall be available in the second half of 2018.

English

English Polski

Polski Germany

Germany LATAM

LATAM Bulgaria

Bulgaria Estonia

Estonia France

France Hungary

Hungary India

India Italy

Italy Kazakhstan

Kazakhstan Romania

Romania Czech Republic

Czech Republic Ukraine

Ukraine United Arab Emirates

United Arab Emirates Latvia

Latvia Lithuania

Lithuania United States of America

United States of America

Turkey

Turkey