Controls of VENTUS air handling units - cost efficiency and comfort.

If we additionally consider the changing demand for process heat or cold throughout the day or the week, resulting from the manner in which a given building or structure is used, we obtain an overestimated size of the device that will not operate in an inefficient manner. In order to reduce the costs of operating the air handling unit, VTS offers advanced control solutions allowing to adjust the performance of the units to the actual conditions inside the building, thus ensuring low operating costs.

Three different operating modes

The user may choose from three individual operating modes: Economy, Optimized and Comfort. Each of these modes offers specific performance parameters: primary value setting, eg temperature in the room, humidity, CO2 level or airflow value, etc.

AHU operating schedule

VTS controls solutions allow to program a weekly AHU operating schedule, taking into account special occasions (annual holidays, bank holidays, days off, etc.). One of the three operating modes available may be selected for each time period. A graphic presentation of the user-configured schedule, relying on visualization tools, is also available.

Advanced control algorithms - minimization of cost

VTS algorithms rely on cascading temperature control in the room, which translates into minimum process heat and cold consumption. Furthermore, control algorithms are responsible for precisely maintaining the preset temperature in the room, at zero hysteresis, by relying on a dynamic, automatic change of supply air temperature settings when operating under the room air temperature regime. This means that the AHU uses the minimum amount of process heat and cold required for obtaining the required parameters.

Automatic air quality control function

VTS offers optimization of energy consumption based on stepless, automatic adaptation of air volume to heating, cooling and ventilation needs. Such an adaptation is based on ensuring proper air quality - temperature, CO2, humidity.

Economic adjustment of fan capacity parameters to the needs of the building

VTS controls solutions offer fan capacity control functions and algorithms that perform electronic measurements and automatically adjust air volume expressed in m³ / h (CAV). Optionally, fixed available pressure expressed in Pa (VAV) may also be measured electronically and adjusted automatically, and the fixed fan speed may be set.

Intuitive and robust AHU control module

HMI Basic

The AHU is operated using a control panel with a simple interface, that prevents any unauthorized changes to the advanced operating settings of the AHU. HMI Basic is a combination of a temperature and humidity sensor with a control panel, all in one casing.

HMI Advanced

- Advanced control panel - the configuration of advanced operating parameters (service access), user-configured parameter settings, reading and canceling error logs.

- Access to monitoring and visualization menus - the AHU may be operated using a control panel with a simple service interface used to change advanced settings and configurations.

- Technical documentation repository - a compilation of current operation and maintenance manuals, as well as service manuals.

- Marketing documentation repository - a compilation of marketing information: catalogues and video tutorials.

HMI Advanced is a dedicated tablet with the Android operating system and the Chrome web browser, allowing the user to comfortably manage and configure the parameters of the device. The user is provided with a one-stop tool for configuring and parameterizing the VENTUS air handling unit, gaining access to documents and information concerning the product, and allowing them to monitor and visualize the operating parameters of devices connected the same network. A 10-inch, high-resolution display allows to conveniently display all AHU data.

The HMI Advanced tablet is delivered together with a communication box. The tablet is mounted to the box using a set of magnets for easy attaching and detaching. The communication box includes a WiFi router for wireless communication with the tablet, and a power supply unit for connecting the tablet. This means that the tablet may be used remotely, whenever within WiFi range.

The diagram showing the power supply connection and the communication paths between the tablet, its communication box and the AHU is presented below:

a) With a single AHU connected

b) With numerous AHUs connected to a single tablet

Real-time, remote monitoring and management of the units operating parameters

VTS provides a standard automation functionality in the form of a factory-implemented VMS (Ventus Management System) an app allowing to remotely monitor, visualize and manage the operating parameters of the units in real-time, via a web browser, using any device.

The Ventus Management System app provides:

- OPTIMIZATION - operating parameters of each functional unit may be easily optimized,

- DIAGNOSTICS - this functionality allows the service staff to perform diagnostic procedures and to offer support remotely,

- ECONOMY - measurement and recording of current operating costs. Ability to define currency and utility prices,

- SIMULATION

- simulation of savings generated thanks to specific functionalities,

- simulation of operating parameters of individual components,

- VISUALIZATION - presentation of all operating parameters of all ventilation units connected to the same network, in the form of charts,

- RECORDING - recording all AHU operating parameters, alarms and warnings, including a text description, date of occurrence and duration of the recorded events,

- CONVENIENCE

- ability to be launched using a web browser on each device,

- available for mobile devices,

- remote access to and remote modification of parameters via LAN or the Internet.

INTUITIVE INTERFACE

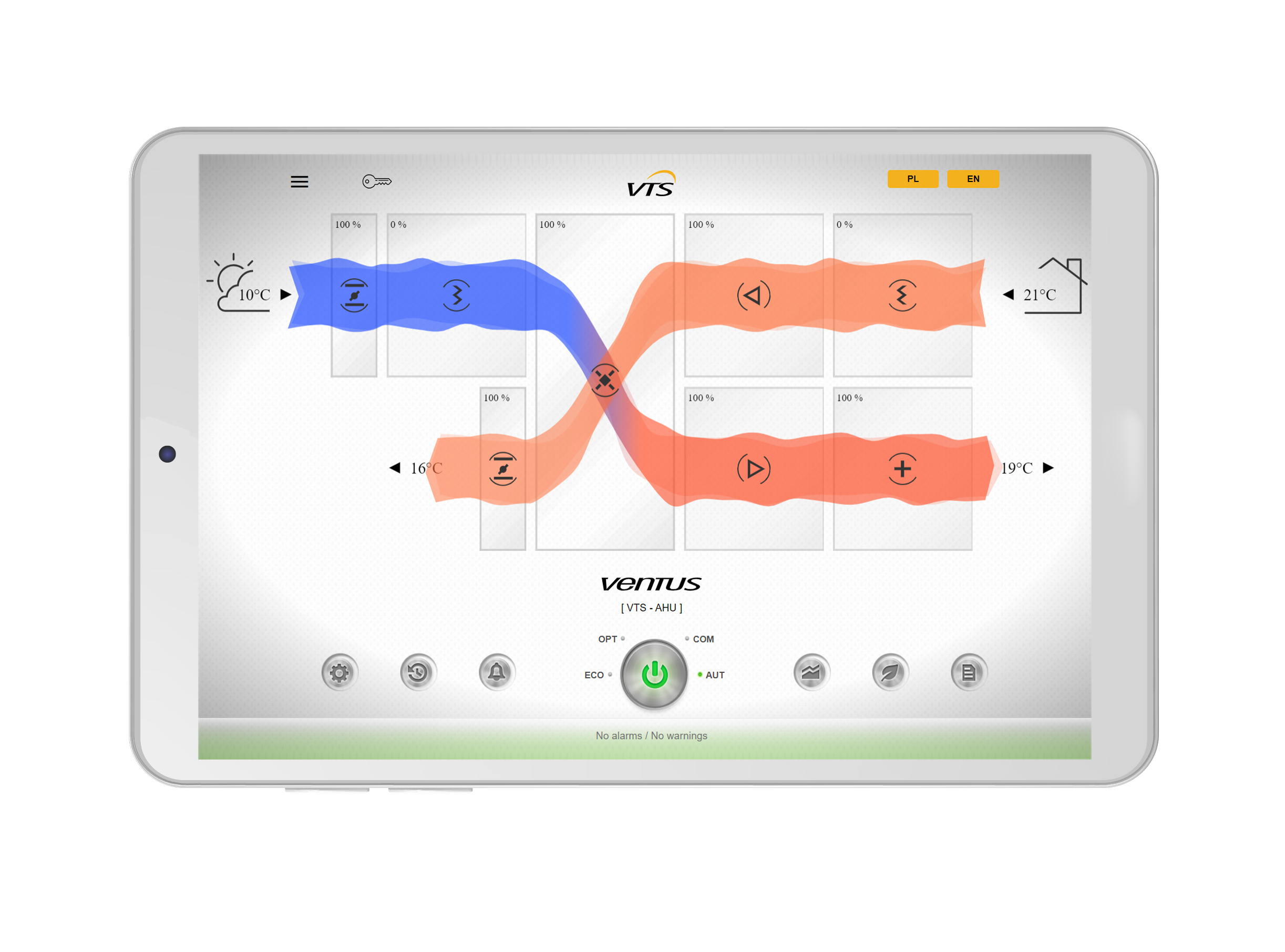

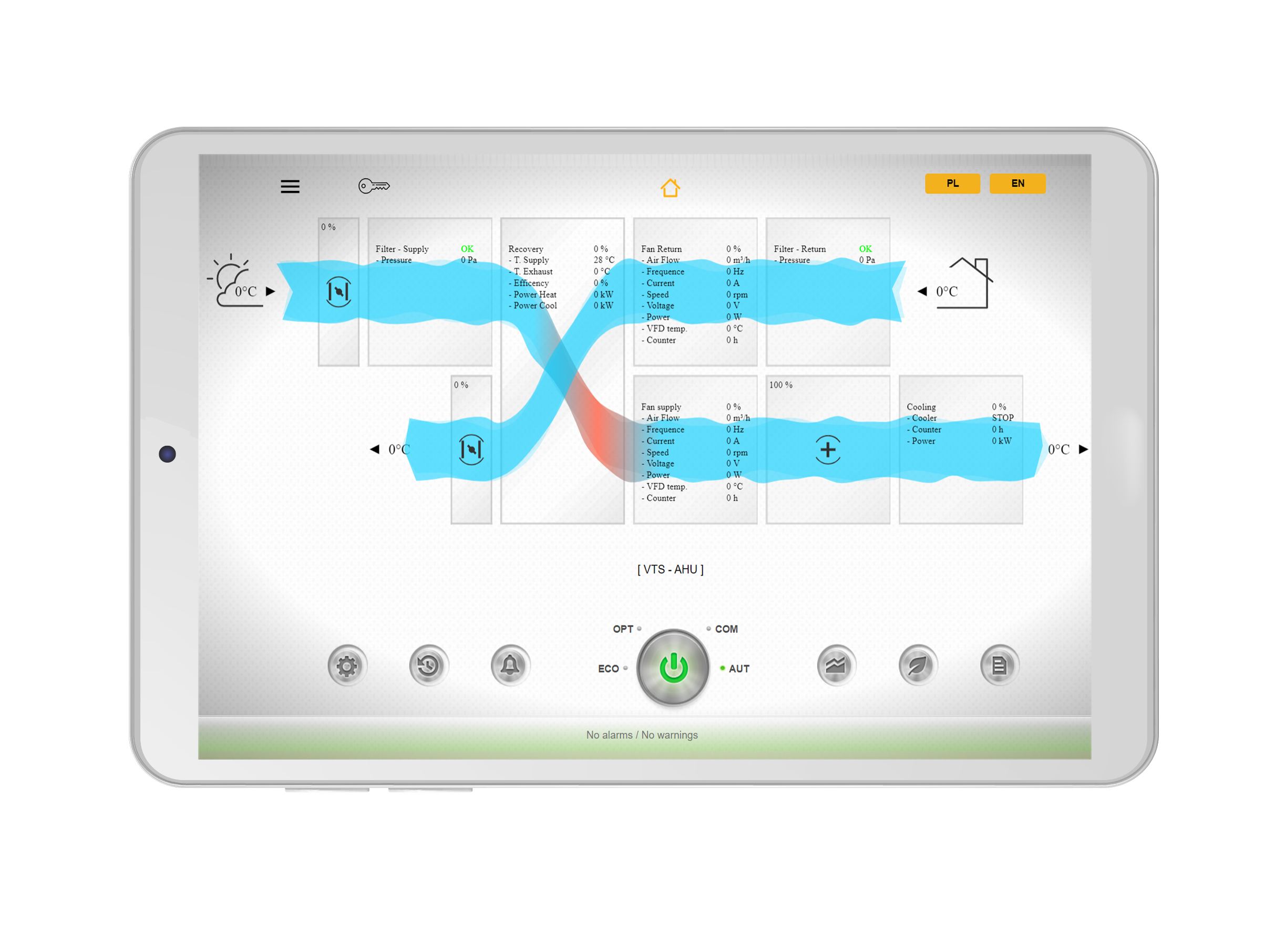

MAIN SCREEN

The main screen includes a graphic diagram of the air handling unit, with air conditioning functions, current settings and parameters clearly marked.

Numerous buttons are also displayed in this window, offering a wide spectrum of AHU management functionalities. This screen may be considered to be the main AHU navigation panel. Using this panel, the user may monitor the status of the AHU, switch on different operating modes or navigate to any of the additional functions.

The AHU diagram offers a series of options, such as displaying the status of each functionality of the unit - informing the user about potential alarms directly via the applicable AHU block. The user may also monitor the parameters of air flowing into and being discharged by the unit.

TIME SCHEDULE

Ability to control the air handling unit based on a predefined schedule is a well-known solution offered by control applications. However, in this case, the novelty consists in the fact that the user may manage schedule settings directly via the diagram - using a standard computer screen and a mouse, or a touch screen of a tablet. The time schedule is designed as a series of scroll bars assigned to specific operating modes. All items are displayed against a timeline. By using scroll bars, the user may adapt the operating schedule of their AHU and improve the economic performance of their ventilation system, all within seconds.

CHARTS

Charts are a tool used for recording all operating parameters of the AHU, as well as for saving them and for displaying historical operating data in the form of a time diagram. This tool was created to help the user develop the most suitable AHU operation schedule, perfectly aligned with the parameters of a given ventilation system. It also aims to improve the economics of system operation and to match the user's personal preferences.

ECO MODE

The ECO mode is used for calculating the savings generated thanks to heat recovery, use of high-performance EC fans and management of the complete unit. State-of-the-art algorithms developed by VTS are relied upon in the process.

All the user needs to do is spend a few minutes to inform the application about the cost of each energy medium used - expressed in any currency. In return, the application will report all savings expressed in kW and in monetary values.

Depending on their preferences, the user may monitor all savings generated jointly by heat recovery, use of high-performance EC fans and advanced VTS control algorithms, or may display a report on a separate, detailed diagram.

BMS

Apart from accessing factory-provided visualizations available via an Internet browser, the user may also connect the AHU’s controls circuits to an external building management system (BMS). By using the BMS system, the user may integrate ventilation, heating and air conditioning systems in order to prevent these installations from opposing each other (simultaneous heating and cooling of the same room by different devices). Communication with the BMS may be based on ModBUS or BacNET TCP/IP protocols, and may support the transfer of nearly all working parameters of the AHUs (all values measured by sensors and transducers and all signals controlling individual actuators (servomotors, fan motors, etc.).

ECO MODE

English

English Polski

Polski Germany

Germany LATAM

LATAM Bulgaria

Bulgaria Estonia

Estonia France

France Hungary

Hungary India

India Italy

Italy Kazakhstan

Kazakhstan Romania

Romania Czech Republic

Czech Republic Ukraine

Ukraine United Arab Emirates

United Arab Emirates Latvia

Latvia Lithuania

Lithuania United States of America

United States of America

Turkey

Turkey